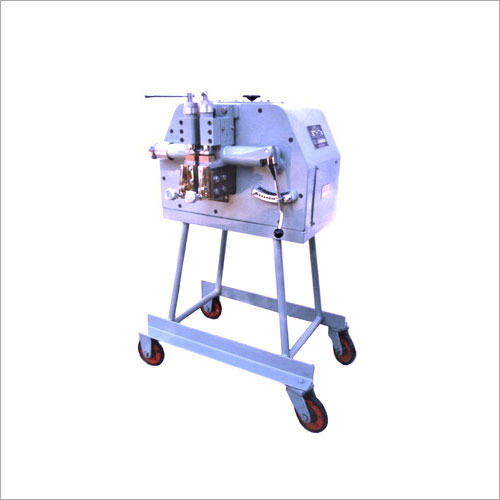

Heavy Duty Copper Strip Butt welder

Product Details:

- Usage Industrial

- Voltage 440 Volt (v)

- Power 440 Volt (v)

- Type Butt welding machine

- Weight 160 Kilograms (kg)

- Click to View more

Heavy Duty Copper Strip Butt welder Price And Quantity

- 160000.00 INR/Piece

- 1 Piece

Heavy Duty Copper Strip Butt welder Product Specifications

- 440 Volt (v)

- Industrial

- Butt welding machine

- 160 Kilograms (kg)

- 440 Volt (v)

Heavy Duty Copper Strip Butt welder Trade Information

- vadodara

- Cash Advance (CA)

- 1 Piece Per Day

- 5 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packing

- Asia

- All India

- MSME Certified

Product Description

A Heavy-Duty Copper Butt Welder is an industrial-grade resistance welding machine designed to perform precision butt welding of copper conductors such as wires, rods, flats, and busbars. It utilizes high electrical current and controlled mechanical pressure to create a seamless, solid joint between two copper ends. These machines are widely used in electrical, automotive, cable manufacturing, and transformer industries, where high conductivity and mechanical strength are critical.

Depending on application size and automation level, machines may come in manual, pneumatic, hydraulic, or servo-operated formats, with optional flash butt welding, annealing, or PLC automation.

| Benefit | How It Helps |

|---|---|

| High Weld Strength | Welded joints are as strong as the parent copper, with low electrical resistance |

| Zero Filler Material Needed | Cost savings and no contamination due to filler-free welding |

| Fast Production Cycles | Weld time typically under 2 secondsgreat for high-volume manufacturing |

| Precision and Repeatability | Ensures uniform weld quality across batches, reducing rework |

| Energy Efficient | Resistance welding is more efficient than arc-based methods for copper |

| Low Maintenance | Simple design with few moving parts; long electrode life with proper cooling |

| Annealing Reduces Brittleness | Built-in annealing softens the weld zone for flexible conductor applications |

| Environmentally Clean | No emissions, fumes, or fluxideal for enclosed factory operations |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS